Municipalities around the world have invested significant resources to develop connected smart cities that use the Internet of Things (IoT) to improve sustainability, safety and efficiency. With this increased demand for IoT experience, the VCU College of Engineering formed the OpenCyberCity testbed in 2022. The 1:12 scale model city provides a realistic, small-scale cityscape where students and researchers can experiment with new and existing smart city technology.

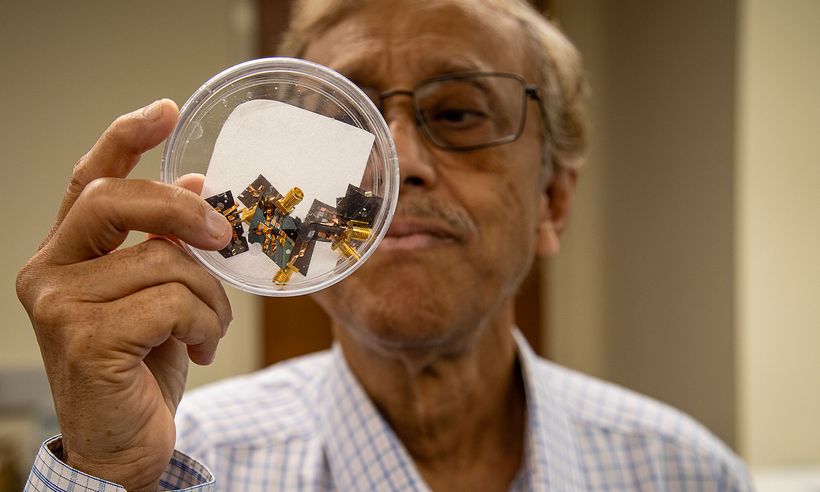

Sherif Abdelwahed, Ph.D., electrical and computer engineering professor, is director of OpenCyberCity. He recently answered some questions about new developments within the testbed.

The OpenCyberCity is a smart city testbed, but are there any real-life cities that one could call a smart city?

Several real-life locales are considered smart cities due to their extensive use of technology and data-driven initiatives to optimize infrastructure and services. Dubai is one of the most notable. They have implemented smart transportation systems, buildings and artificial intelligence to transform the city’s operations and make them more efficient.

Other reputable smart cities include Singapore and Seoul, which utilize smart energy management, smart transportation and comprehensive data analytics for improved urban planning and services. Seoul, in particular, has an initiative with smart grids and connected street lights, which VCU Engineering’s own OpenCyberCity test bed is working to implement.

How does the OpenCyberCity address privacy? With so much technology related to monitoring, how are individual citizens protected from these technologies?

Privacy is a major concern for smart cities and it is one of the main research directions for VCU Engineering’s OpenCyberCity. We are developing several techniques to prevent unwanted surveillance of personal information. Sensitive data is protected by solid protocols and access restrictions that only allow authorized users to view the data. Our aim is to find a reasonable middle ground between technological progress and privacy rights, staying within legal and ethical bounds.

Some techniques to address privacy concerns include:

- Data Anonymization: This makes it difficult to trace back information to individual identities. Within the testbed, we will evaluate how to protect individual privacy while maintaining data utility and assess the impact on data quality.

- Secure Data Storage and Transmission: Encrypt data to protect it from unauthorized access. In the smart city testbed, these access control mechanisms will be implemented within the testbed’s infrastructure. We will also test different data handling processes and access control models to determine their ability to safeguard sensitive data.

- Privacy Impact Assessments: Regularly evaluate potential privacy risks of new smart city projects in order to mitigate them and ensure the ethical handling of data by those with access.

- Policy and Regulation Development: Data and insights generated from OpenCyberCity experiments can inform the development of cybersecurity policies and regulations for smart cities.

How is the College of Engineering’s OpenCyberCity test bed different from similar programs at other institutions?

While other universities have similar smart-city-style programs, each has their own specialty. The VCU College of Engineering’s OpenCyberCity test bed focuses on real-world contexts, creating a physical space where new technologies, infrastructure, energy-efficient transportation and other smart city services can be tested in a controlled environment. Our lab monitors real-time data and develops smart buildings, smart hospitals and smart manufacturing buildings to enhance the city’s technologies.

Recent additions to the OpenCyberCity allow for expanded research opportunities like:

- Advanced Manufacturing: Students can apply advanced manufacturing techniques in a controlled environment. They can also test new materials, processes and automation technologies to improve efficiency and product quality.

- Energy Efficiency Testing: Environmental engineers and sustainability experts can evaluate energy consumption patterns within the smart manufacturing unit to implement energy-saving measures and assess their impact on sustainability.

- Production Optimization: Manufacturers can use real-time data from the smart manufacturing unit to optimize production schedules, minimize downtime and reduce waste. Predictive maintenance algorithms also help prevent equipment breakdowns.

- Education and Training: Hands-on experience with state-of-the-art manufacturing technologies helps train the workforce of the future.

- Integration with Smart City Services: Data generated by the manufacturing unit can be integrated with smart city services. For example, production data can inform supply chain management and energy consumption data can contribute to overall city energy efficiency initiatives.

How has the OpenCyberCity changed in the last year? Is the main focus still data security?

What started with research examining, analyzing and evaluating the security of next-generation (NextG) applications, smart city operations and medical devices has expanded. Data security is now only one aspect of OpenCyberCity. Its scope has grown to encompass more expansive facets of cybersecurity like automation and data analytics in the domain of smart manufacturing systems.

The implementation of a smart manufacturing system in 2023 is something students really enjoy. Thanks to the vendor we used, undergraduate students had the option to develop functionality for various features of the manufacturing plant. Graduate students were also able to research communications protocols and cybersecurity within the smart manufacturing system.

What does the smart manufacturing system entail and what kind of work is occurring within that system?

An automated system is there for students to work with. Robot arms, microcontrollers, conveyor belts, ramps, cameras and blocks to represent cargo form an environment that emulates a real manufacturing setting. We’re currently brainstorming an expansion of the smart manufacturing system in collaboration with the Commonwealth Cyber Initiative (CCI). We plan to set up two building models, one for manufacturing and one for distribution, linked by a sky bridge conveyor system that moves items between the locations.

Students work to leverage convolutional neural networks that use images to facilitate machine learning. When paired with the advanced cameras, it forms a computer vision system that can accurately place blocks in a variety of lighting conditions, which can be a challenge for other systems.

By having to optimize the communication protocols that command the smart manufacturing system’s robotic arms, students also get a sense for real-world constraints . The Raspberry Pi that functions as the controller for the system is limited in power, so finding efficiencies that also enable stability and precision with the arms is key.

Is there an aspect of cybersecurity for these automated systems?

Yes. Devices, sensors and communication networks integral to the IoT found in smart manufacturing systems and smart cities generate and share vast amounts of data. This makes them vulnerable to cybersecurity threats. Some of the issues we look to address include:

- Data Privacy: Smart systems collect and process vast amounts of data, including personal and sensitive information. Protecting this data from unauthorized access and breaches is a top priority.

- Device Vulnerabilities: Many IoT devices used in smart systems have limited computational resources and may not receive regular security updates, making them vulnerable to exploitation.

- Interconnectedness: The interconnected nature of smart city components increases the attack surface. A breach in one system can potentially compromise the entire network.

- Malware and Ransomware: Smart systems are susceptible to malware and ransomware attacks, which can disrupt services and extort organizations for financial gain.

- Insider Threats: Employees with malicious intent or negligence can pose significant risks to cybersecurity.

Potential solutions to these problems include data encryption, frequent software updates, network segmentation with strict access controls, real-time intrusion detection (with automated responses to detected threats), strong user authentication methods, security training for users and the development of well-designed incident response plans.