Chemical and Life Science Engineering Professor Michael “Pete” Peters, Ph.D., is investigating more efficient ways to manufacture biologic pharmaceuticals using a radial flow bioreactor he developed. With applications in vaccines and other personalized therapeutic treatments, biologics are versatile. Their genetic base can be manipulated to create a variety of effects from fighting infections by stimulating an immune response to weight loss by producing a specific hormone in the body.

Ozempic, Wegovy and Victoza are some of the brand names for Glucagon-Like Peptide-1 (GLP-1) receptor agonists used to treat diabetes. These drugs mimic the GLP-1 peptide, a hormone naturally produced in the body that regulates appetite, hunger and blood sugar.

“I have a lot of experience with helical peptides like GLP-1 from my work with COVID therapeutics,” says Peters. “When it was discovered that these biologic pharmaceuticals can help with weight loss, demand spiked. These drug types were designed for people with type-2 diabetes and those diabetic patients couldn’t get their GLP-1 treatments. We wanted to find a way for manufacturers to scale up production to meet demand, especially now that further study of GLP-1 has revealed other applications for the drug, like smoking cessation.”

Continuous Manufacturing of Biologic Pharmaceuticals

Pharmaceuticals come in two basic forms: small-molecule and biologic. Small-molecule medicines are synthetically produced via chemical reactions while biologics are produced from microorganisms. Both types of medications are traditionally produced in a batch process, where base materials are fed into a staged system that produces “batches” of the small-molecule or biologic medication. This process is similar to a chef baking a single cake. Once these materials are exhausted, the batch is complete and the entire system needs to be reset before the next batch begins.

“ The batch process can be cumbersome,” says Peters. “Shutting the whole process down and starting it up costs time and money. And if you want a second batch, you have to go through the entire process again after sterilization. Scaling the manufacturing process up is another problem because doubling the system size doesn’t equate to doubling the product. In engineering, that’s called nonlinear phenomena.”

Continuous manufacturing improves efficiency and scalability by creating a system where production is ongoing over time rather than staged. These manufacturing techniques can lead to “end-to-end” continuous manufacturing, which is ideal for producing high-demand biologic pharmaceuticals like Ozempic, Wegovy and Victoza. Virginia Commonwealth University’s Medicines for All Institute is also focused on these production innovations.

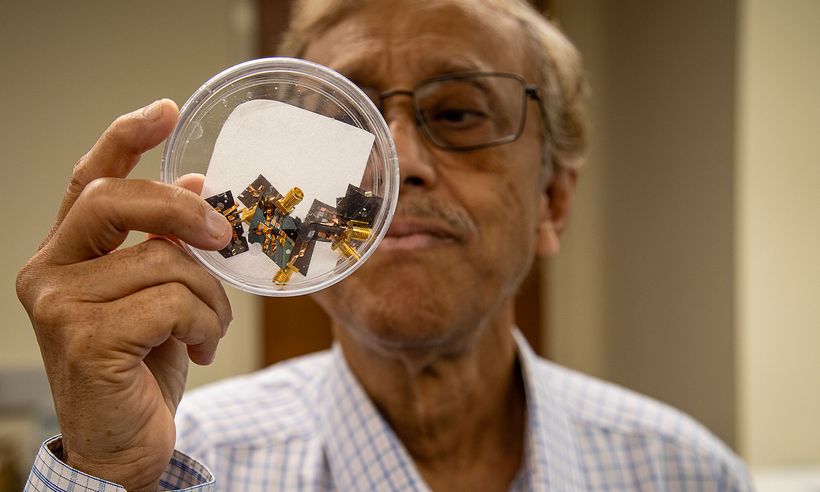

Peters’ continuous manufacturing system for biologics is called a radial flow bioreactor. A disk containing the microorganisms used for production sits on a fixture with a tube coming up through the center of the disk. As the transport fluid comes up the tube, the laminar flow created by its exiting the tube spreads it evenly and continuously over the disk. The interaction between the transport medium coming up the tube and the microorganisms on the disk creates the biological pharmaceutical, which is then taken away by the flow of the transport medium for continuous collection.

Flowing the transport medium liquid over a disc coated with biologic-producing microorganisms allows the radial flow bioreactor to continuously produce biologic pharmaceuticals.

“There are many advantages to a radial flow bioreactor,” says Peters. “It takes minutes to switch out the disk with the biologic-producing microorganisms. While continuously producing your biologic pharmaceutical, a manufacturer could have another disk in an incubator. Once the microorganisms in the incubator have grown to completely cover the disk, flow of the transport medium liquid to the radial flow bioreactor is shut off. The disk is replaced and then the transport medium flow resumes. That’s minutes for a production changeover instead of the many hours it takes to reset a system in the batch flow process.”

The Building Blocks of Biologic Pharmaceuticals

Biologic pharmaceuticals are natural molecules created by genetically manipulating microorganisms, like bacteria or mammalian cells. The technology involves designing and inserting a DNA plasmid that carries genetic instructions to the cells. This genetic code is a nucleotide sequence used by the cell to create proteins capable of performing a diverse range of functions within the body.

Like musical notes, each nucleotide represents specific genetic information. The arrangement of these sequences, like notes in a song, changes what the cell is instructed to do. In the same way notes can be arranged to create different musical compositions, nucleotide sequences can completely alter a cell’s behavior.

Microorganisms transcribe the inserted DNA into a much smaller, mRNA coded molecule. Then the mRNA molecule has its nucleotide code translated into a chain of amino acids, forming a polypeptide that eventually folds into a protein that can act within the body.

“One of the disadvantages of biologic design is the wide range of molecular conformations biological molecules can adopt,” says Peters. “Small-molecule medications, on the other hand, are typically more rigid, but difficult to design via first-principle engineering methods. A lot of my focus has been on helical peptides, like GLP-1, that are a programmable biologic pharmaceutical designed from first principles and have the stability of a small-molecule.”

The stability Peters describes comes from the helical peptide’s structure, an alpha helix where the amino acid chain coils into a spiral that twists clockwise. Hydrogen bonds that occur between the peptide’s backbone creates a repeating pattern that pulls the helix tightly together to resist conformational changes.

“It’s why we used it in our COVID therapeutic and makes it an excellent candidate for GLP-1 continuous production because of its relative stability,” says Peters.

Programming The Cell

Chemical and Life Science Engineering Assistant Professor Leah Spangler, Ph.D., is an expert at instructing cells to make specific things. Her material science background employs proteins to build or manipulate products not found in nature, like purifying rare-earth elements for use in electronics.

“My lab’s function is to make proteins every day,” says Spangler. “The kind of proteins we make depends entirely on the project they are for. More specifically I use proteins to make things that don’t occur in nature. The reason proteins don’t build things like solar cells or the quantum dots used in LCD TVs is because nature is not going to evolve a solar cell or a display surface. Nature doesn’t know what either of those things are. However, proteins can be instructed to build these items, if we code them to.”

Spangler is collaborating with Peters in the development of his radial flow bioreactor, specifically to engineer a microorganismal bacteria cell capable of continuously producing biologic pharmaceuticals.

“We build proteins by leveraging bacteria to make them for us,” says Spangler. “It’s a well known technology. For this project, we’re hypothesizing that Escherichia coli (E. coli) can be modified to make GLP-1. Personally, I like working with E. coli because it’s a simple bacteria that has been thoroughly studied, so there’s lots of tools available for working with it compared to other cell types.”

Development of the process and technique to use E. coli with the radial flow bioreactor is ongoing.

“Working with Dr. Spangler has been a game changer for me,” says Peters. “She came to the College of Engineering with a background in protein engineering and an expertise with bacteria. Most of my work was in mammalian cells, so it’s been a great collaboration. We’ve been able to work together and develop this bioreactor to produce GLP-1.”

Other Radial Flow Bioreactor Applications

Similar to how the GLP-1 peptide has found applications beyond diabetes treatment, the radial flow bioreactor can also be used in different roles. Peters is currently exploring the reactor’s viability for harnessing solar energy.

“One of the things we’ve done with the internal disc is to use it as a solar panel,” says Peters. “The disk can be a black body that absorbs light and gets warm. If you run water through the system, water also absorbs the radiation’s energy. The radial flow pattern automatically optimizes energy driving forces with fluid residence time. That makes for a very effective solar heating system. This heating system is a simple proof of concept. Our next step is to determine a method that harnesses solar radiation to create electricity in a continuous manner.”

The radial flow bioreactor can also be implemented for environmental cleanup. With a disk tailored for water filtration, desalination or bioremediation, untreated water can be pushed through the system until it reaches a satisfactory level of purification.

“The continuous bioreactor design is based on first principles of engineering that our students are learning through their undergraduate education,” says Peters. “The nonlinear scaling laws and performance predictions are fundamentally based. In this day of continued emphasis on empirical AI algorithms, the diminishing understanding of fundamental physics, chemistry, biology and mathematics that underlie engineering principles is a challenge. It’s important we not let first-principles and fundamental understanding be degraded from our educational mission, and projects like the radial flow bioreactor help students see these important fundamentals in action.”