2 min

National Science Foundation funds research into quantum material-based computing architecture at the VCU College of Engineering

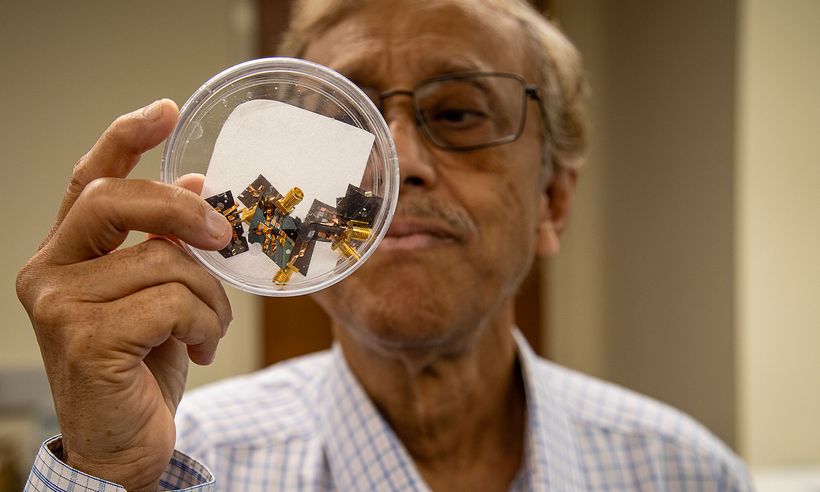

Supporting the development of advanced computing hardware, the National Science Foundation (NSF) awarded Supriyo Bandyopadhyay, Ph.D., Commonwealth Professor in the Department of Electrical and Computer Engineering at the Virginia Commonwealth University (VCU) College of Engineering with more than $300,000 to develop processor-in-memory architecture using quantum materials. “This is one of the first mainstream applications of quantum materials that have unusual and unique quantum mechanical properties,” Bandyopadhyay said. “Quantum materials have been researched for more than a decade and yet there is not a single mainstream product in the market that utilizes them. We want to change that.” The four-year project, titled “Collaborative Research, Foundations of Emerging Technologies: PRocessor In Memory Architecture based on Topological Electronics (PRIMATE),” aims to advance computing hardware and artificial intelligence by integrating topological insulators and magnetic materials. Topological insulators are a special material with an electrically conductive surface and an insulated interior. They have special quantum mechanical properties like “spin-momentum locking,” which ensures the quantum mechanical spin of an electron-conducting current on the surface of the material is always perpendicular to the direction of motion.This marks the first time such quantum materials will be used in a processor-in-memory system. “We place a magnet on top of a topological insulator,” Bandyopadhyay said. “We then change the magnetization of the magnet by applying mechanical strain on it. That changes the electrical properties of the topological insulator via a quantum mechanical interaction known as exchange interaction. This change in the electrical properties can be exploited to perform the functions of a processor-in-memory computer architecture. The advantage is that this process is fast and extremely energy-efficient.” If successful, this approach could reduce energy use and dramatically speed up computing by moving data processing into the memory itself. It addresses the longstanding “memory bottleneck,” the slowdown caused by computers constantly needing to move data back and forth between processor and memory. These efficiencies could make advanced AI more efficient and accessible, paving the way for the first commercially viable applications of quantum materials.. The research is a collaboration with University of Virginia professors Avik Ghosh and Joseph Poon. A VCU Ph.D. student will work on the project and receive training in fabrication, characterization and measurement techniques, preparing them to lead in the rapidly evolving field of computing hardware.